CENTERLINE PREFAB

ADD SPEED

Greatly reduce the time of building envelope installation

- Fast-Track, Systemized Panel Manufacturing

- Efficiencies Compress the Construction Schedule

- Indoor Production Means No Weather Delays

- Site Prep and Panel Construction Can Occur Simultaneously

- Reduced Multi-Trade Vendor Coordination

- Faster Installation Due to Prefab Panelization

ADD VALUE

Reduce the cost of your project

- Lightweight Panels Lower Structural Requirements

- Smaller Footings / Foundations

- Reduced Jobsite Labor & Crew Sizes

- No Jobsite Scaffolding Required

- Decreased Volume of Project Concrete

- Reduced Drywall Furring, Boxing and Strapping

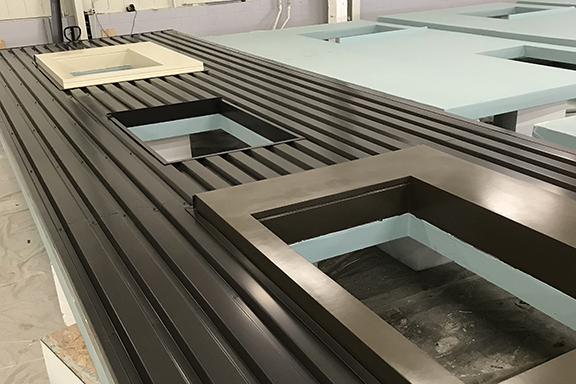

ADD QUALITY

Temperature-controlled factories with exacting specs

- ISO-Engineered Components

- Q/A Programs Ensure Quality-Controlled Workmanship

- Strict Adherence to Manufacturers’ Temp/Humidity Guidelines

- Extensive Architectural and Finish Options

- Superior Fire, Acoustical and Thermal Performance

- Superior Long Term Durability

- Industry-Leading Warranty

Prefabricated Panels = Savings

LESS MANPOWER

Easy installation means less labor. Reductions can be as much as going from 60 workers to 6 when compared to typical on-site construction methods.

LESS TIME

Reduce your building envelope installation time by up to eighty percent when compared to conventional field-installed construction methods.

LESS WEIGHT

Take advantage of continuous insulation panel walls that can have up to ninety percent less weight than other panels and conventional wall types.

Systems

The logical evolution of the best performing products engineered into a comprehensive prefabrication solution. StoPanel delivers what stand-alone components cannot: higher quality and dependability fortified by third-party testing and code compliance.

Our systematized approach to panelized construction offers many benefits over traditional precast panels. StoPanels are lightweight, energy efficient, durable and require only a fraction of the typical installation time.

We are a proud member of the StoPanel network of affiliates and adhere strictly to their standards for quality and workmanship.

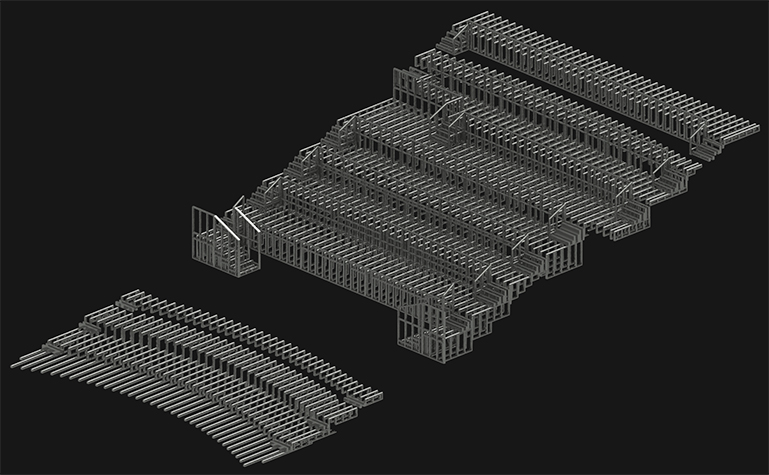

Cold-Formed Metal Stud Bearing Panels, Assemblies, and Multi-Trade Solutions

GRAND RAPIDS VETERANS’ HOME

Grand Rapids, MI

GRAND RAPIDS VETERANS’ HOME

Grand Rapids, MI

DETAILS

- Computer Modeled Solutions

- Engineered

- Made Using American Rolled, Cold-formed Steel

- Constructed in the Centerline Facility

- Strategic Alliances with Mechanical and Electrical Firms

APPLICATION EXAMPLES

- Exterior Walls

- Interior Walls and Components

- Stadia Seating Frames

- MEP Racks

- Decoupled MEP Assemblies

- Head Walls

Project Profiles

We’ve helped to eliminate weather delays and reduce construction time on various projects across the United States using prefabrication. Click the photos below to learn more about a few of our projects.

“When we prefabricated all of Arcadia Flats’ facade, the time spent on the job was a fraction of what it would have been if we had to build each panel onsite.”

Matt Novak, Leader of Project Management

10 Critical Questions

If an owner is considering a prefab manufacturer, these are good questions to ask.

Centerline Prefab can answer yes to each of these questions.

Are they a true manufacturer and not doing construction in a warehouse?

Is there an established QA/QC program?

Are the assemblies engineered and tested?

Is the facility dedicated for manufacturing prefabricated assemblies?

Are they International Code Council certified?

Is a warranty provided for the prefabricated assemblies?

Do they have a network of companies to provide support?

Do they have experience designing and manufacturing assemblies for all climate zones?

Are they capable of putting multiple finish types on their assemblies?

Are window/glazing solutions able to be provided within their assemblies?